Reobars and Reinforcing Bars: Key Safety Measures to Follow

What Are Reobars and Why Are They Critical in Construction?

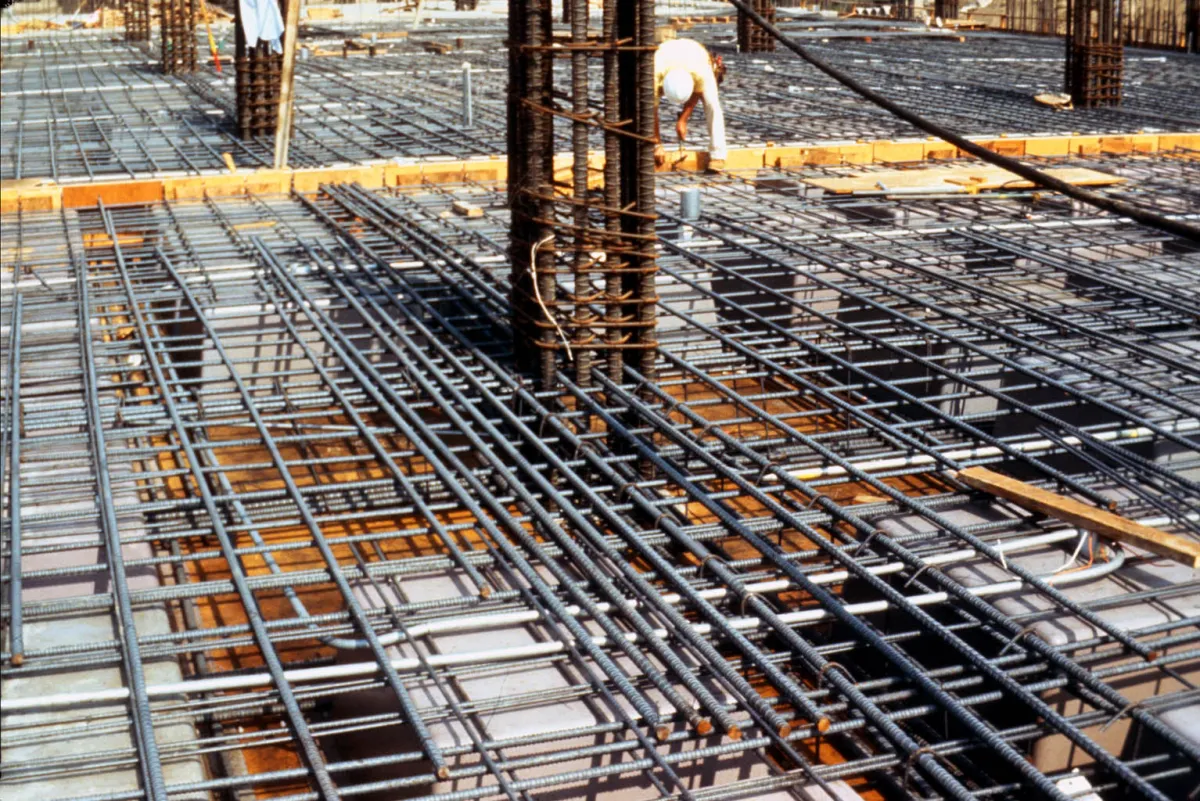

Reo bars, short for reinforcing bars, are steel rods embedded within concrete structures to create reinforced concrete systems. These cylindrical steel components feature ribbed surfaces that create mechanical bonds with concrete, transforming brittle concrete into a composite material capable of withstanding both compression and tension forces.

The primary function of reinforcing bar centres on addressing concrete’s inherent weakness in tensile strength. While concrete excels at resisting compression, it fails under tension loads. Reo bars compensate for this limitation by:

- Absorbing tensile stresses that would otherwise cause concrete to crack

- Distributing loads evenly throughout the structure

- Preventing catastrophic failure during seismic events or extreme weather

In Australian construction, reo bars hold particular significance due to the country’s diverse climate conditions and seismic activity. Coastal projects require rust-resistant reo bar options to combat salt-air corrosion, extending infrastructure lifespan significantly. The harsh Australian environment, from tropical cyclones in Queensland to bushfire-prone regions, demands reinforced concrete structures that can withstand extreme conditions.

Australian building codes mandate specific reo bar grades and placement requirements for different structural applications. From high-rise developments in Sydney and Melbourne to mining infrastructure in remote locations, reinforcing bars ensure structural integrity across the continent’s varied construction landscape. You’ll find these critical components in everything from residential foundations to major infrastructure projects like bridges and tunnels.

What Are the Primary Safety Hazards Associated with Rebars?

Rebar safety hazards present serious risks that can result in severe workplace injuries and long-term health complications. Understanding these dangers helps you implement appropriate protective measures on construction sites.

1. Impalement Injuries

Impalement injuries represent the most severe threat from exposed reinforcing bars. Workers who fall onto protruding rebars can suffer deep puncture wounds that damage internal organs, blood vessels, and bones. These incidents often require emergency surgery and extended recovery periods.

2. Lacerations and Cuts

Lacerations and cuts occur frequently when workers accidentally contact sharp rebar ends during routine construction activities. The jagged edges of cut reinforcing steel can slice through clothing and skin, causing wounds that require immediate medical attention.

3. Rusted Rebar Dangers

Rusted rebar dangers compound injury severity significantly. Corroded steel harbours bacteria, including tetanus spores, which can cause life-threatening infections when they enter wounds. The rough surface of oxidised metal creates irregular cuts that are difficult to clean and heal slowly.

4. Falls from Heights

Falls from scaffolding, ladders, or elevated work platforms onto exposed rebars create the highest risk scenarios. The combination of gravitational force and sharp steel points can result in fatal impalement injuries, making fall protection systems essential around reinforcing steel installations.

What Protective Measures Can Prevent Rebar-Related Injuries?

Protective caps for rebars are the most effective way to prevent impalement injuries. When possible, you should use steel-reinforced caps instead of standard plastic ones. Steel caps offer better impact resistance and durability on busy construction sites. These caps fit tightly over exposed rebar ends, creating a blunt surface that greatly reduces the risk of penetration during accidental contact.

When protective caps aren’t available, you can bend rebar ends downward at a 90-degree angle or greater. This alternative method eliminates sharp vertical protrusions while still keeping the structure strong. The bent configuration redirects potential impact forces horizontally instead of allowing direct penetration.

Temporary barriers are important for creating safe zones around exposed rebar areas. Here are some examples of protective installations you can consider:

- Guardrails positioned at standard working heights around areas with a lot of rebar

- Safety netting stretched across places where workers might fall onto exposed bars

- Perimeter fencing to prevent unauthorised access to dangerous sections

Chain and shade mesh installations serve two purposes – protecting workers from direct contact while also reducing the risk of materials scattering. The mesh creates visual barriers that help workers see where the dangers are, especially in areas with multiple protruding bars.

You must make sure all protective measures stay secure throughout the construction process. Regular inspections will confirm that caps haven’t been moved by weather or construction activities, ensuring consistent protection across your worksite.

How Should Rebars Be Properly Stored and Maintained to Enhance Safety?

Proper rebar storage begins with strategic placement away from pedestrian walkways and vehicle routes. You should designate specific storage areas that don’t interfere with daily construction activities, reducing the likelihood of workers tripping over scattered reinforcing bars. Stack rebars horizontally on wooden blocks or purpose-built racks, maintaining clear separation between different sizes and grades.

Regular inspections for rust form the backbone of effective rebar maintenance. You need to examine stored reinforcing bars weekly, paying particular attention to areas where moisture accumulates. Look for:

- Surface discolouration indicating early oxidation

- Flaking or pitting that compromises structural integrity

- White or reddish deposits suggesting advanced corrosion

Coating rebars with appropriate protective treatments significantly extends their lifespan, particularly in coastal Australian environments where salt exposure accelerates deterioration. Epoxy coatings provide excellent corrosion resistance, whilst galvanised rebars offer superior protection for long-term projects. You can also apply temporary rust-preventive oils during storage periods, ensuring the coating remains compatible with concrete bonding requirements when installation begins.

Store coated rebars separately from untreated ones to prevent cross-contamination and maintain clear identification systems for different treatment types.

Why Is Worker Training Essential for Safe Handling of Rebars?

Worker training forms the foundation of effective construction safety awareness when dealing with reinforcing steel. You need comprehensive education programmes that highlight the specific dangers rebars present, from impalement risks to cuts from sharp edges. Training sessions must address the unique hazards of working with protruding steel, particularly in Australian construction environments where weather conditions can accelerate corrosion.

Best practices for safe handling include proper lifting techniques, maintaining awareness of rebar locations, and understanding correct installation procedures. Your workers should learn to:

- Identify hazardous rebar configurations before beginning work

- Use appropriate personal protective equipment consistently

- Implement proper communication protocols when working near exposed steel

- Recognise when protective measures require immediate attention

Handling reo bars safely requires ongoing reinforcement of safety protocols. Regular training updates ensure your team stays current with evolving safety standards and techniques. Construction sites implementing structured training programmes report significantly fewer rebar-related injuries compared to those relying solely on informal instruction.

The measurable impact on workplace accident reduction demonstrates training’s value. Sites with comprehensive rebar safety education experience up to 60% fewer steel-related incidents, protecting both workers and project timelines while maintaining compliance with Australian safety regulations.

What Role Do Regulatory Standards Play in Rebar Safety Compliance?

OSHA 1926.701(b) establishes clear requirements for protecting workers from protruding reinforcing steel hazards. This regulation mandates that all vertical rebar extending more than 1.5 metres above working surfaces must be protected to prevent impalement injuries. The standard applies to both temporary and permanent installations across construction sites.

Regulatory standards for rebars specify approved protection methods that meet safety requirements:

- Impact-resistant caps made from steel-reinforced materials

- Wooden planking secured over rebar arrays

- Protective covers designed to withstand 200-pound loads

Compliance requirements extend beyond basic protection installation. You must ensure protective measures remain intact throughout construction phases and replace damaged caps immediately. Regular documentation of safety measures helps demonstrate adherence during inspections.

Australian construction sites following these standards experience significantly fewer rebar-related injuries. The regulations create accountability frameworks where site supervisors must verify protection systems daily. Non-compliance results in work stoppages and substantial penalties, making adherence both a safety imperative and business necessity.

Proper implementation of these regulatory standards transforms dangerous rebar installations into manageable safety challenges through systematic protection protocols. Check out more about how Mesh Fencing and Site Mesh Improve Security and Safety.

How Can Inspection Software Tools Improve Enforcement of Safety Measures?

Inspection software tools are changing the way construction teams monitor and enforce rebar safety protocols on Australian building sites. These digital platforms take the uncertainty out of safety compliance monitoring by offering real-time tracking features that guarantee every exposed reinforcing bar is properly safeguarded.

Customisable Checklists for Rebar Safety Assessments

Modern inspection applications provide customisable checklists specifically tailored for rebar safety evaluations. You have the flexibility to set up these digital forms to include mandatory checks for:

- Protective cap installation on all exposed ends

- Proper bending of protruding steel where applicable

- Barrier placement around high-risk areas

- Worker compliance with handling procedures

Comprehensive Audit Trails and Corrective Action Management

The result tracking feature generates thorough audit trails that record every safety inspection. When supervisors spot areas that are not compliant, the software instantly activates corrective action management workflows, assigning specific tasks to responsible team members with clear deadlines.

Digital Documentation for Regulatory Inspections and Insurance Assessments

Digital documentation is extremely valuable during regulatory inspections and insurance assessments. You can access timestamped photographs, GPS coordinates, and detailed compliance reports that prove your commitment to following Reobars and Reinforcing Bars: Key Safety Measures to Follow.

Seamless Integration with Project Management Systems

These tools work smoothly with existing project management systems, enabling safety managers to create automated reports for stakeholders. The consistent enforcement capabilities minimise human error in safety assessments while ensuring no exposed rebar remains unprotected throughout your construction site.

What Additional Safety Considerations Support Overall Construction Site Protection?

Fall protection systems become essential when workers operate above areas containing exposed rebars. These systems prevent catastrophic injuries that occur when personnel accidentally fall onto protruding reinforcing steel. Harnesses, safety nets, and guardrails create multiple layers of protection around elevated work zones.

Scaffold netting importance extends beyond basic fall prevention. Quality netting systems catch falling tools and debris that could otherwise strike workers below or damage exposed rebar installations. This protection proves particularly valuable during concrete pours when multiple trades work simultaneously around reinforcing steel.

Chain & shade mesh provides dual functionality in rebar zones. The mesh creates physical barriers that prevent accidental contact with protruding bars whilst offering worker material protection mesh capabilities. These systems shield both personnel and stored materials from weather exposure and falling objects.

Urban construction sites benefit significantly from mesh installations through noise reduction properties. The fabric dampens construction sounds, reducing community complaints whilst maintaining safety standards around rebar areas. This acoustic benefit supports project continuity and community relations during extended construction phases.

Conclusion

Rebar safety summary demonstrates that preventing injuries on construction sites requires unwavering commitment to established protocols. You must implement protective caps, proper storage procedures, and comprehensive worker training consistently across every project phase. Maintaining compliance with regulatory standards protects both your workforce and your business operations.

The safety measures outlined in this guide work together as an integrated system. When you combine protective equipment with digital inspection tools and fall protection systems, you create multiple layers of defence against rebar-related incidents. Your dedication to these practices directly impacts worker wellbeing and project success.

Reobars and Reinforcing Bars: Key Safety Measures to Follow become second nature when you prioritise safety culture development. Regular training sessions, equipment maintenance, and adherence to Australian building standards ensure your construction sites operate at the highest safety levels possible.